mohitsinghi35@gmail.com - GST NO. : 06AAACH5844E1ZT

- Send Email

50 Piece (MOQ)

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

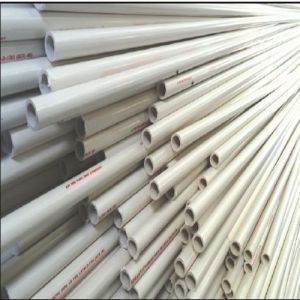

| Material | PVC (Polyvinyl Chloride) |

| Uses | For Connecting Pipes In Agricultural Irrigation Systems |

| Type | Pipe Fittings |

| Click to view more | |

Product Details

Agricultural PVC fittings are crucial components in irrigation and water supply systems, offering durability and efficiency. Here's an overview of key aspects related to agricultural PVC fittings

Types of Agricultural PVC Fittings

1. Moulded Fittings: These are manufactured according to specific standards like IS 7834 and are widely used for connecting pipes in various configurations such as elbows, tees, and couplers

2. Fabricated Fittings: These are custom-made connecting pipes, offering flexibility in design to fit specific needs and are also used for various purpose.

Key Features of Agricultural PVC Fittings

Material: Made from polyvinyl chloride (PVC), these fittings are resistant to corrosion, impact, and UV rays, ensuring long-lasting performance.

Standards: Conform to Indian standards such as IS 4985 for pipes and IS 7834 for moulded fittings, ensuring quality and reliability

Joint Types: Commonly available in Selfit (solvent cement joint) and Ringfit (rubber ring joint) types, each offering different installation advantages.

Agricultural PVC fittings are used in :

- Irrigation Systems: Efficient water distribution for crops.

- Potable Water Supply: Safe transportation of drinking water.

- Drainage Systems: Effective removal of excess water from fields

Types of Agricultural PVC Fittings

1. Couplings: Used to connect two pipes of the same diameter.

2. Elbows: Allow for a change in direction of the pipe (e.g., 90-degree or 45-degree angles).

3. Tees: Connect three pipes, allowing for branching in the system.

4. Reducers: Used to connect pipes of different diameters, such as after a tee connection .

Installation Procedures for Agricultural PVC Fittings

1. Cutting: Cut the pipe squarely using tools like a plywood cutting saw.

2. Deburring/Beveling: Ensure the cut is clean and free of debris. A slight bevel can aid in pipe insertion. Remove any burrs from the pipe ends to ensure smooth entry into fittings.

3. Cleaning and Preparation: Clean both the pipe ends and fitting sockets to remove dirt and moisture. Dry-fit the pipe to ensure proper fit before applying solvent cement.

4. Priming and Solvent Cement Application: Apply primer to both the pipe end and fitting socket to soften the surfaces. Use solvent cement that matches the pipe material (e.g., uPVC solvent cement for uPVC pipes)

5. Assembly: Insert the pipe into the fitting socket immediately after applying solvent cement, Rotate the pipe slightly to distribute the cement evenly, Hold the assembly briefly to prevent push-out.

6. Final Touches: Remove excess solvent cement with a clean cloth to prevent weakening the joint

Looking for "Agriculture Pipe Fittings" ?

Explore More Products